PSHE

Plate & Shell heat exchangers

Plate and shell heat exchangers represents the ideal combination of plate heat exchanger and shell&tube heat exchangers. They combine the best feature of both: efficiency of plate heat exchangers and safety of shell&tube heat exchangers.

The inner plate are welded together eliminating gaskets, so this type of exchanger can work with temperatures from -200 ˚C up to 500 ˚C. These exchangers are manufactured in capacities up to 100.000 kW and working pressures up to 200 bar. Their efficiencies is very high, up to 95%.

They can be used in district heating systems most often as primary heat exchanger. Since it is possible to clean one side of exchanger very easy, therefore this type of exchanger is often used as heat exchanger in systems of large boiler plants which serve to protect the boiler from impurities that can reach from the heating pipelines. They are also used as condensers, evaporators and with in systems for heating and cooling the oil. More and more, this type of heat exchanger is used in function economizer and recuperator for waste heat gases.

This type of exchanger is ideal solution for systems where there are large and asymmetric flows of working fluids.

Main advanteges of plate and shell heat exchangers

- small installation and surface area due to compact design

- close temperature approach between the hot and cold side by multipass media, providing high heat recovery

- a self-cleaning effect with a high wall shear stress due to plate design – turbulent flow enables reduce of fouling and extend the time between cleaning

- low cost for steel structures and foundations by a low weight of the equipment

- fully welded design eliminates gaskets, ensuring high reliability and resistance to failure and leakage, as often experienced with gasketed plate and frame units

- wide range of plate materials provides high corrosion resistance

- range of plate and nozzle sizes, combined with flexibility of shell design and number of nozzles provides optimized solution

- shells can be tailored to increase the volume, for evaporating and condensing duties, such as kettle reboilers

- high heat transfer coefficients

- low liquid inventory provides a rapid start-up and a fast response to changes in process set points and upsets

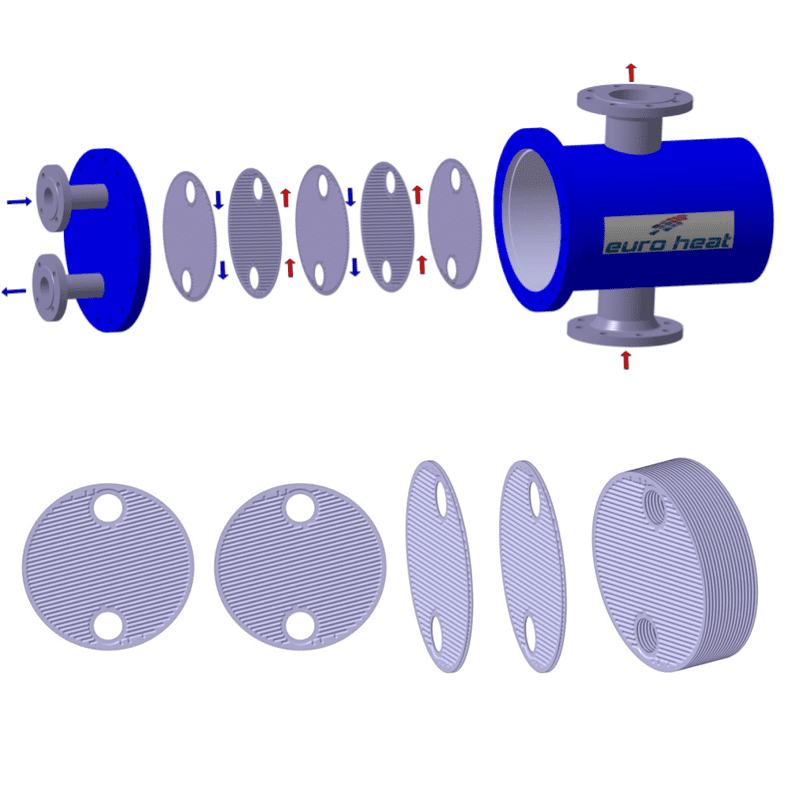

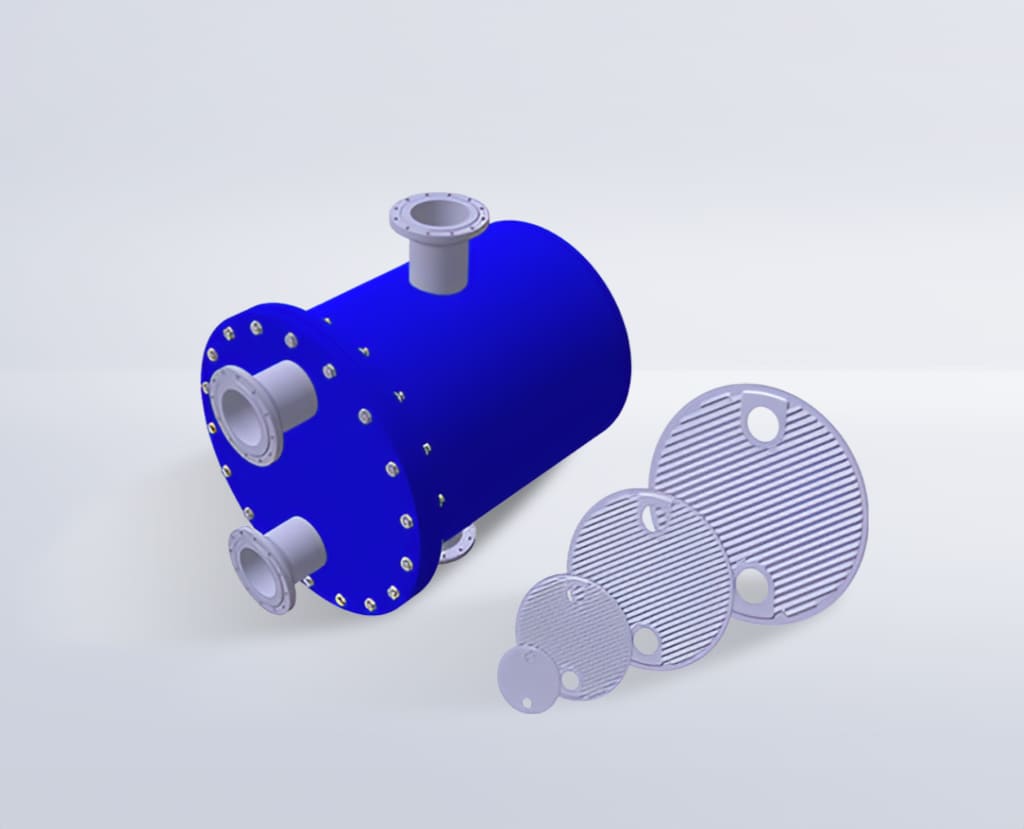

Plate pack

Plate pack is the core and main component of PSHE. It is assembled from inner plates, which are welded together and give strong and safety construction. Size, deep of plate, number of passes number of plates, type of construction of plate pack are selected custom for each task.

| Type | Plate diameter (mm) | Thicnkes of plates (mm) | Area per plate (m²) | Plate side nozzle, DE | Shell size nozzle, DN | Maximum number of plates |

|---|---|---|---|---|---|---|

| P 100 | 120 | 0,8-1,2 | 0,017 | 25 | 25-80 | 100 |

| P 200 | 190 | 0,8-1,2 | 0,028 | 25 | 25-250 | 180 |

| P 350 | 320 | 0,7-1,5 | 0,079 | 50 | 25-300 | 400 |

| P 500 | 454 | 0,7-1,5 | 0,16 | 80 | 25-350 | 600 |

| P 600 | 562 | 0,7-1,5 | 0,26 | 100 | 25-500 | 600 |

| P 750 | 740 | 0,8-1,5 | 0,43 | 150 | 25-500 | 800 |

| P 1000 | 980 | 0,8-1,5 | 0,73 | 200 | 25-700 | 1000 |

Plate materials

- AISI 316L

- AISI 904L

- 254 SMO

- Alloy C22, C276

- Duplex

- Titanium gr.1, gr.11

- Nickel

- Others on request

Flow directors / stoppers

- EPDM

- Silicones

- PTFE

- Fluoride silicone

- Graphite

Shell materials

- Carbon steel

- AISI 316L

- AISI 904L

- 254 SMO

- Alloy C22, C276

- Duplex

- Titanium

- Others on reques

Example of Plate and Shell marking:

P 1000 – 170 H 1-1 1R FW – Model of plate and shell heat exchanger

P 1000 – type of plate and shell heat exchanger

170 – number of inner plates

1-1 – number of passes (one pass on both sides)

1R – number of plate packs

FW – fully welded model